Product Catalog

Explore Our Products

To learn more about a product, please contact your local Renown representative for technical information, and save drilling and service time.

Browse by Category

Featured Products

-

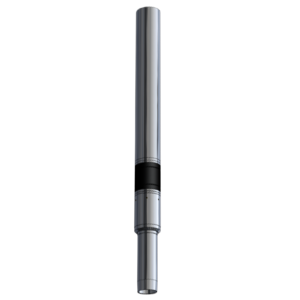

Model ’H’ Liner Packing

More InformationThe Model ‘H’ Liner Packer is a unique liner top system as it has a hydraulic chamber built into the tool itself, allowing for a larger I.D. on the setting tool and more pack off at the liner packer element.

-

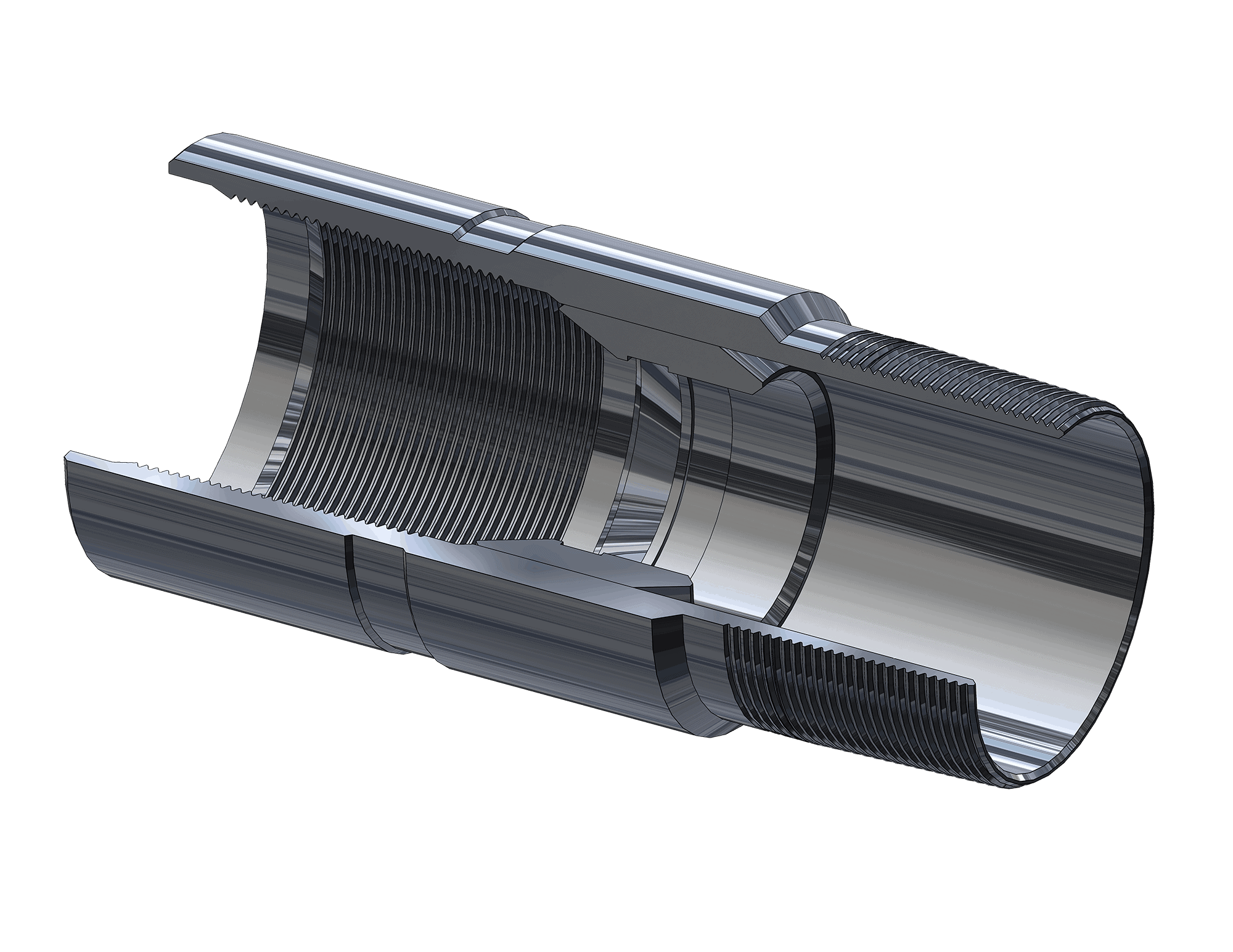

‘HDSR’ Retrievable Liner Hanger Packer

More InformationA retrievable hydraulic set and release Liner Top Hanging Packer with bi-directional slips.

-

Model ’HDSR-2’ Retrievable Liner Hanger Packer

More InformationThe Model ‘HDSR-2’ Liner Hanger Packer is a premium grade system.

Reduce lead times & well costs with our patented one-trip RIP & Liner Hanger Combo.

We have achieved third party thermal ratings and scrub test over 600°F (315°C) to back our liner systems. We carry the float and centralization equipment to complete any liner.